Success Story: Fathom + Form

An industry leader in architectural fabrication builds better products faster with LightWELD.

What’s a Success Story?

There are a lot of reasons why our customers invest in LightWELD: it might solve a specific problem for them, or help them be more productive, or they might just be excited by the technology. Whatever the reason, we love talking to them and learning about their businesses.

Our success stories are a closer look at some of our customers, what they’re working on, and how LightWELD has helped them find success. We hope that their stories can help give you a better idea of how the industry is using and benefiting from LightWELD.

About the Company

Fathom + Form specializes in premium custom architectural metal work, doors, windows, and surfaces tailored to unique and high-end projects. By focusing on craftsmanship and leveraging an eye for aesthetics, the company has grown rapidly since it was founded in 2016.

From elegant handrails in ritzy homes to stylish restaurants and even the pivoting door at Chanel’s flagship store, Fathom + Form has been busy growing their portfolio with a range of residential and commercial projects. One thing remains consistent, however: clients are willing to compromise on neither form nor function.

Learn more about Fathom + Form’s projects here.

Industry

Architectural

Company Size

11-50

Location

Los Angeles, CA

The Challenge

Fathom + Form’s clients accept nothing but the best. And their projects involve more than just one fabricator – bringing a refined final product to life requires close collaboration between architects, designers, engineers, and fabricators from across half a dozen contractors. With such lofty standards and so many moving parts, Fathom + Form must be fast, flexible, and laser-focused on the details, all while making a profit.

According to founder Preston Johnston, “We aim to create things that are simple and elegant looking, but in reality, our products are often complex and require a lot of planning.”

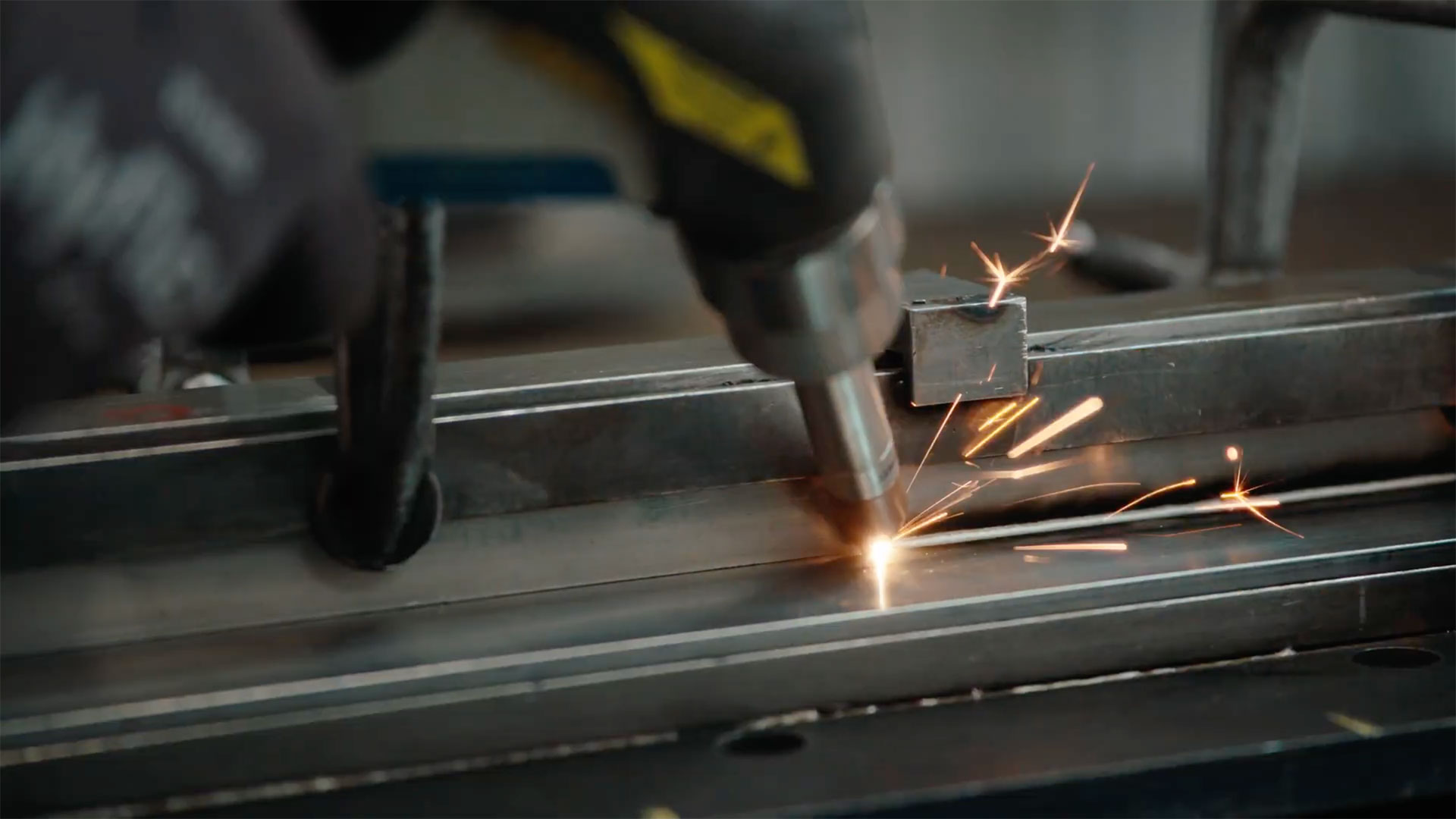

Naturally, welding is a critical part of the company’s fabrication process. And, in the world of architectural metalwork, there are several things for welders to worry about at once.

Strength and structural integrity are important, of course, but many elements also must be truly waterproof, which can be tricky to achieve with standard arc welding. To add more complexity, warping must be avoided to preserve appearances and stay within tight tolerances.

Speaking of aesthetics, the company must often grind arc welds to improve the appearance of the weld seam and remove spatter. While not a showstopper, the extra labor time can eat into Fathom + Form’s margins.

Trying to mitigate persistent welding challenges, Johnston’s team ended up eliminating nearly all MIG welding in favor of TIG. “We switched over to TIG welding instead of MIG welding to better control the weld deposition and distortion,” says the founder.

While the switch to TIG helped, rising material costs and lead times, combined with the increasing complexity of Fathom + Form’s products, encouraged the fabricator to explore other welding technologies.

The Solution

“As we were transitioning to TIG, conversations around laser welding were coming up more and more often.”

Johnston and his team began work on developing their own line of products back in 2020. While researching fabrication methods for complex steel Z and L profiles for door interlocks, they discovered a Swiss manufacturer using laser welding to accomplish something similar.

“That pushed us to explore what laser welding could do for us,” says Johnston, “Fortunately, we had some experience already with a laser cutter.”

The team’s research led them to LightWELD. As soon as their new laser welder was delivered, the team got to work. According to Johnston, “We set off to identify the practical applications of laser welding for our line of doors and windows. We were able to rapidly prototype, and we quickly felt very confident about our version one.”

Ultimately, the team was able to develop a process to build their proprietary door and window profiles for a fraction of the cost of sourcing the profiles they needed.

Although Fathom + Form looked to laser welding to solve a specific challenge, they have since experienced additional benefits in function, productivity, and aesthetics.

“Once the powder coating goes on, it looks just like a formed piece of metal. You need to get up close to it to even tell that it’s a weld, which is amazing for us.”

After integrating laser welding into a variety of their products and joints, Johnston has been pleased at the lack of warping and naturally waterproof welds. His team has also saved time on post-processing, finding that it’s possible to skip the grinding while building a better-looking product.

Johnston views laser welding as a key part of his vision for Fathom + Form as an industry leader. Remaining competitive is tricky for any business, but it can be even more complicated in such a complex and demanding industry. Fortunately, LightWELD has provided the company with a big advantage.

“Someone else might be able to get close to what we’re doing but their price point’s going to be way higher. LightWELD lets us provide a better product at a lower price point.”